Introduction

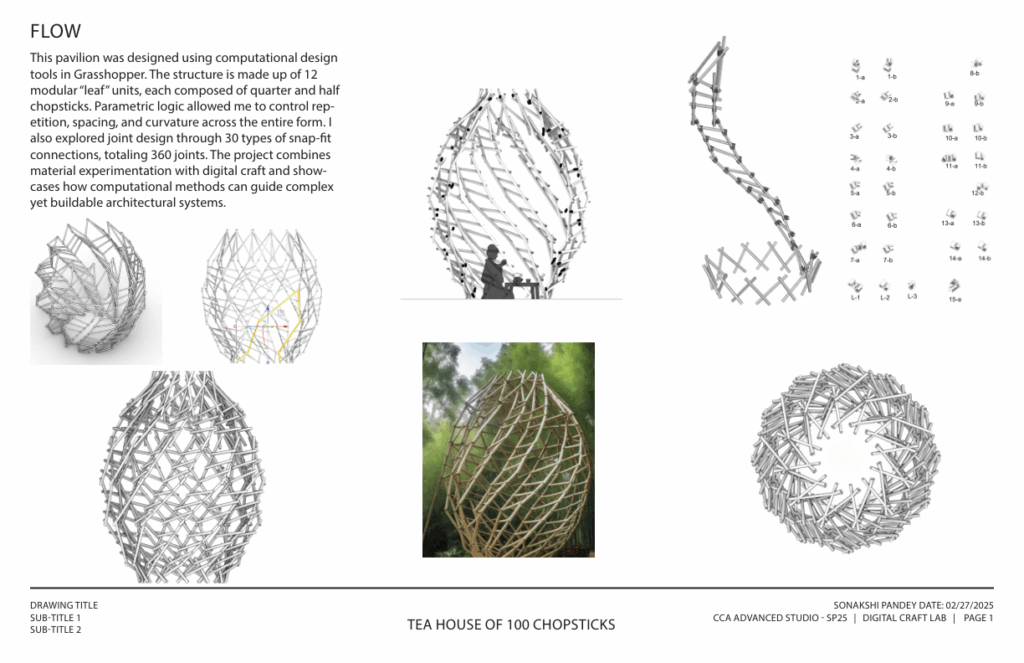

For her CCA Advanced Studio – SP25 digital craft lab, designer Sonakshi Pandey set herself an unusual challenge: could a pavilion be built entirely from chopsticks? The resulting project, “Tea House of 100 Chopsticks,” uses computational design tools to transform a humble material into a gracefully curved, modular structure. Parametric modelling in Grasshopper allowed Pandey to adjust repetition, spacing, and curvature across the entire form and explore how digital craft methods can guide the assembly of complex yet buildable archit

ectural systems.

Design Concept and Parametric Workflow

The pavilion is composed of twelve modular “leaf” units, each made from both quarter-length and half-length chopsticks. In her description of the workflow, Pandey notes that parametric logic allowed her to control how the 12 leaves repeat and twist, producing an organic, shell-like volume. The design process involved adjusting the spacing and curvature in the model, running physical tests, and iteratively refining the geometry to achieve a continuous yet buildable surface.

Each “leaf” unit acts as a flexible rib in the pavilion. By mirroring and repeating the leaves around a central axis, Pandey created a structure reminiscent of a seed pod or cocoon. The parametric model let her test different curvatures and densities digitally before committing to the physical build. This integration of digital design and physical craft is central to the project’s appeal: it demonstrates how computational tools can inform the making of tactile, human-scale spaces.

Material Calculations

The project’s title comes from the large number of chopsticks required. Pandey explains that each leaf uses twelve quarter-length chopsticks and ten half-length chopsticks, so the full pavilion of twelve leaves requires 144 quarter chopsticks and 120 half chopsticks. Additional quarter chopsticks were used in the base structure to stabilise the pavilion. The precise counts were derived from the parametric model, which ensured that each piece aligned correctly when assembled.

Joint Design and Assembly

A key innovation of the project is its joint system. Rather than relying on glue or fasteners, Pandey designed thirty types of snap-fit joints to connect the chopsticks. Each joint type corresponds to a specific angle or node condition within the pavilion. Because there are twelve leaves, the total number of joints is 30 × 12 = 360.

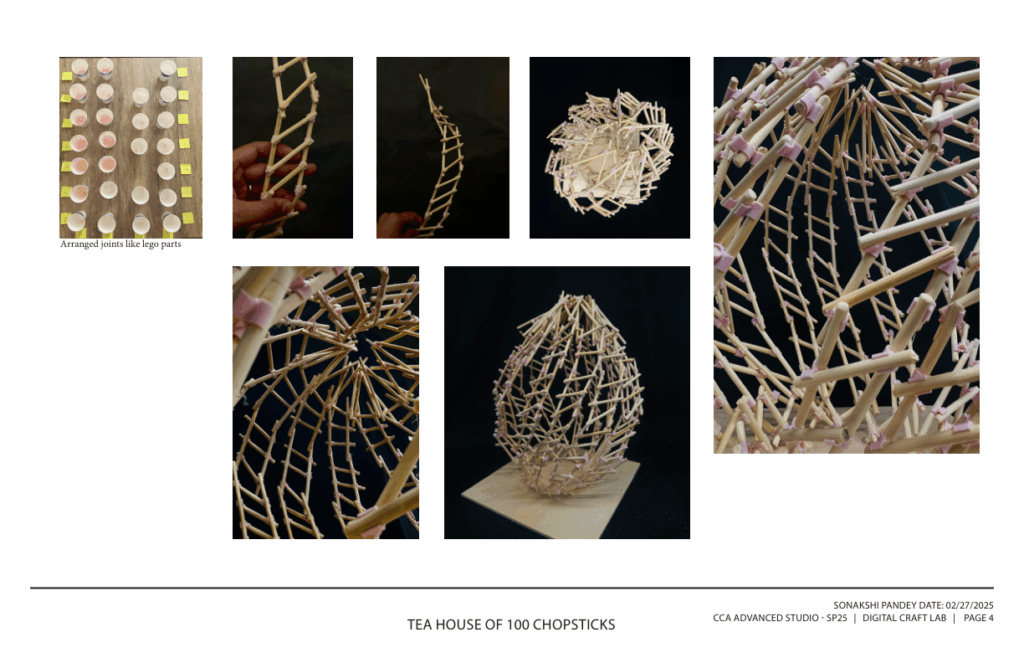

The joints were modelled digitally and then fabricated from small plastic components that grip the chopsticks like Lego pieces. This modular system allowed the leaves to be assembled, disassembled, and adjusted during the build process. The physical model photographs show how the joints are laid out like Lego parts before assembly and how individual leaves can be snapped together to form a larger whole.

Physical Fabrication and Aesthetic Qualities

Once the digital model was finalised, Pandey moved into the physical build. Photographs of the process show individual leaf units being assembled with red connectors, then combined into a spherical shell. The snap-fit joints allowed the structure to be built in sections; as the leaves were added, the pavilion took on a woven, basket-like appearance. Inside, a person can sit comfortably, illustrating the scale and potential use of the space.

The completed Tea House of 100 Chopsticks sits on a simple wooden base, emphasizing the delicate interplay between the linear chopsticks and the curving form they create. Close-up images reveal a texture reminiscent of basketry or latticework, while the overall silhouette evokes organic forms found in nature. The project highlights the beauty of repetitive elements and demonstrates how a computational design process can produce a handmade object that feels both precise and hand-crafted.

Significance

Sonakshi Pandey’s tea house is more than a playful exploration of chopsticks. It underscores how digital design can inform material experimentation, bridging the gap between computational precision and tactile craft. By developing a parametric model that accounted for every chopstick and joint, Pandey was able to translate a complex digital form into a buildable structure using everyday materials. The project invites viewers to reconsider the potential of simple components when guided by thoughtful design and careful fabrication.

In an era where digital tools can sometimes feel removed from the physical world, Tea House of 100 Chopsticks serves as a reminder that computation and craft can be mutually reinforcing. The project’s success lies in its seamless integration of parametric logic, material efficiency, and human-scale experience—qualities that continue to inspire designers exploring the intersection of digital and physical making

Leave a Reply